Knowledge

Management For Open Innovation: Collaborative Mapping Of Needs And Competencies

Augusta Maria Paci, Cecilia Lalle, Maria Stella Chiacchio, Consiglio

Nazionale delle Ricerche, Rome, Italy

ABSTRACT:

In view of the European knowledge

economy, a full participatory process among different units and different

organizations can be established to identify solutions that meet the

expectations representing high value achievements of different

stakeholders’ objectives. The paper describes a reference model for a

collaborative knowledge management (Co-KM) in an open innovation environment

for futuring technology analysis (FTA) to support industrial innovation in the

knowledge economy. This model with methods and tools allows K-community to

operate more effectively and to proceed faster toward the common goal.

Furthermore, it permits the mapping of community’s needs and

competencies. Two experiences of Co-KM carried on inside a European project are

reported.

Keywords: Open model, Collaborative method, Lean

environment

1. Introduction

Over the last five

years, the European Commission has brought forward a policy and strategy

development for the broad-based innovation towards the European knowledge economy. Key importance is

given to the improvement of knowledge generation and to a faster and lean

knowledge transfer among research organization, academy, industry and

government.

Industry plays an important role in the global economic development. Industrial success in current times needs to face higher efficiency in production processes and, also, sustainability aspects for environment and society (Jovane, 2005). Today, with the implications of globalization and economic recession, industries face fundamental changes due to globalized production and markets, shortened product/process life-cycle, rapid progress in technologies and turbulent business environment. Normally the solution is sought in the reduction of production costs. Fostering the knowledge economy, the competition will shift from cost reductions to high value. Companies need to rely upon innovative and new enabling technologies with related business models for new products and processes.

This new behaviour requires: a renewed research-innovation chain, research and development projects on specific technologies, time-to-market of new industrial technologies. The early forms of coordinating initiatives among public research, industries and policy-makers have been the European Technology Platforms, the major organizations held by the relevant and interested stakeholders. These new knowledge entities have the objective to set out collectively the research and innovation strategies built by different stakeholders at different decision-making levels. The results of collaboration of the European Technology Platforms are their Strategic Research Agendas and Roadmaps that have involved the work of thousands of people, (Eumecha-Pro, 2007; European, 2006; Futman, 2004; INEMI, 2007; I*PROMS, 2004; ITEA, 2004).

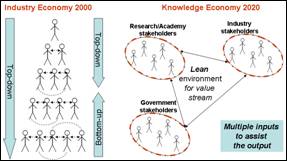

Figure 1: Evolution Of Problem Solving Strategies

This paper describes the collaborative knowledge management (Co-KM) reference model. This model is applied to open innovation environment and supports futuring technology analysis (FTA) for industrial innovation. Co-KM allows to operate more effectively and to proceed faster toward the common goal within networks of research/academy, industry and governments. Two experiences on Roadmapping activities are also reported.

2. Reference Model

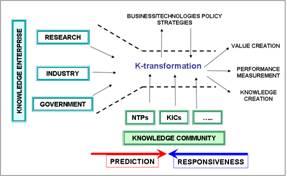

The main result of the research work is a reference model of the collaborative knowledge management (Co-KM) inside an open and lean environment applied to the field of futuring technology analysis (FTA) to support industrial innovation in the knowledge economy. This is an open model for the collaborative process among different stakeholders that applied the SECI modalities. It could be considered an original reference model of the knowledge management for innovation in the K-economy, since it treats the process as an open model where K-enterprise and K-community are inter-related in the K-transformation process.

In this open information model, the convergence of knowledge concepts and elements, coming from stakeholders of the K-enterprise, permits the creation of a collaborative knowledge management environment (Chesbrough, 2006). It treats expectations and future goals enabling inflows and outflows of the knowledge domain though a continuous participatory process involving different actors of the K-community. Information modelling receives, from this convergence, the support to a fast changing environment and sustains people and their capacity of aligning their knowledge to future innovation mapping needs and competencies through a collaborative process (Figure 2). The development of the open model allows the integration of prediction and responsiveness for continuous innovation contributing to foster the transition to high value stream.

Figure 2: Collaborative Process Based On Open Model (Epplab

Elaboration Of Chesbrough, 2006; Figure 1.2 P.3)

Knowledge

management, as an adding value process, is essential to:

Ų develop stable interaction for innovation internally and externally;

Ų exploit the potential of the “knowledge base” of organizations such as SMEs, academy, government;

Ų add value to technical and business requirements to foster innovation development;

Ų involve people into a strategic process.

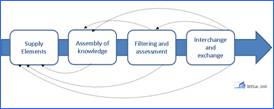

3. End-to-end Visibility

Process

The lean environment

benefits of knowledge management methods and tools for the end-to-end

visibility. This is a new process for the full participation of different

stakeholders enabling the ranking, the prioritization and the

traceability of the whole advancements. The end-to-end visibility process is

supported by a rolling programme. The development of the end-to-end visibility

of life-cycle of large innovation processes is depicted in the Figure 3.

Figure 3: End-to-end Visibility

The

building blocks of this process, each of them interlinked with the others, are:

Ų Supply elements referring to: foresight studies, roadmaps, working documents, best practices, scientific papers, project deliverables, surveys;

Ų Assembly of knowledge in selected domain, made with:

Ų K-transfer models, taxonomy and ontology (domain related),

Ų ICT tools for information management (xls and word files, catalogues, data-bases, templates),

Ų Mixed qualitative/quantitative method of data collection and data processing;

Ų Filtering and assessment achieved through validation procedures (team building, workshops with mixed multi-level stakeholders, questionnaires, interviews with key opinion leaders of industry);

Ų Interchange and exchange achieved with dissemination tools (conference, seminars, publications).

A rolling programme is applied to manage simultaneously large innovation processes. Regarding futuring-oriented technology analysis, the applications of Foresight, Roadmapping, Implementation, and Monitoring (FRIM) constitute the core of the “support service”. FRIM carries on a process with different and sliding phases with several interactions. The rolling programme allows this continuous process of interactions and validation of results among stakeholders at different levels (Figure 4) (Cagnin et al. 2008). It enables to manage simultaneously large innovation processes running and tracing advancements of knowledge generation. The novelty lies in the fact that this knowledge process is directly managed and experienced by individual actors and interested groups.

Figure 4: The Rolling Cycle-Oriented Programme

The FRIM applications have the scope to ensure effectiveness, efficiency and consistency to FTA for emerging production systems. The four Futuring activities are:

1.

Foresight (F): demand-driven process for

future technologies with attractiveness and feasibility analysis. It supports

scenario-buildings, initial and continuous technologies updating and networked

R&I policies for the knowledge economy.

2.

Roadmapping (R): a community-driven open

process for screening and planning of the prioritization of next generation

technologies with feasibility and traceability of industrial expected impacts

with time horizons (Westkämper, 2006).

3.

Implementation (I): instruments-driven process

for coordination of efforts and of stakeholders’ interventions. It

develops plans of priorities to minimizing threats, maximizing opportunities

and reducing risks for new products/services, processes and business models.

This is supported by the analysis on ground of best practices and pilot

projects.

4. Monitoring (M): governance-driven process for assessment and evaluation of results of the research-innovation process. This activity is related to market knowledge capture and supports costs and especially value benefits analysis of options choice in strategic fields of industrial interests in terms of sustainability. The experiences in §4 report about the application of the collaborative knowledge management for open roadmapping.

The described roadmapping application is a full participatory process that applies the SECI model (Nonaka, 1995):

Ų Socialization:

sharing tacit knowledge that is built upon existing experiences. It constitutes

the design phase of the roadmapping process.

Ų Externalization:

articulating knowledge and developing the organization “intellectual

capital” through dialogue. It constitutes the implementation phase of the

roadmapping process.

Ų Combination:

expliciting the borders of expectations in terms of “competitive

advantage”. It constitutes the use phase of roadmaps in industrial

sectors.

Ų Internalization: participating in a learning process. It constitutes the reconfiguration phase of the roadmapping process.

4. Experiences Of Co-Km

The new model on knowledge management for innovation, proposed in this paper, was developed and applied within the second FRIM activity - roadmapping - carried on within a FP6 SSA project at EU level in 2006-2007.

In this section two experiences of Co-KM model application within the project K-community are reported:

Ų the first experience regards the side of research;

Ų the second one focuses on knowledge elaborated within the side of industry.

4.1. The

Side Of Research Of K-community

In

The 28 roadmappers were split up into 5 working groups, according to the related five priority macro-areas. Each working groups were composed by 4-6 experts. The roadmappers processed together, through a bottom up approach, different types of preparatory material. These material, distributed on a CD-ROM for handy use and uploaded onto Intranet, consisted of:

Ų A repository of more than 450 technology fact sheets provided by 63 roadmappers representing about 190 researchers from major organizations. These technology fact sheets were preliminary results from the analysis of more than 90 sources from vision and SRA published by European Technology Platforms.

Ų Input from European Commission by the project officer.

Ų Enabling technologies pre-catalogue and taxonomy for a reference classification of technologies.

This amount of material was processed to produce a ranking of strategic

research areas of industrial interests. At the end of the workshop, 14

strategic research areas were produced to support the knowledge transformation

of European industry. Looking to the

end-to-end visibility process, this experience can be positioned in the second

phase of the process (assembly of K), as reported in Figure 3. The outcome of

the roadmapping meeting - supervised and approved by the High Management

Board of the project - formed the input

for the following phase (filtering and assessment), in which the results were

put in discussion within the K-community of the project.

4.2. The

Side Of Industry Of K-community

A joint conference between research and industry was held in

Ų seek industrial feedback on the strategic research areas;

Ų understand sectors requirements and priorities;

Ų rank the priorities (sense of urgency).

The 150 delegates from Industry, Research and Government K-enterprises, were split up into 6 groups, according to the following six sectors macro-areas:

ii. Transport area

iii. Materials & basic products area

iv. ICT area

v. Consumer Products area

vi. Food/Pharma/Bio area

The six panel sessions, chaired by industrial participants, discussed and identified industry research macro-sectoral R&D priorities in a strong collaborative way. Within these workshops, delegates processed and discussed the following preparatory material:

Ų around 14 strategic research areas (reported in the 4.1 section), produced by roadmappers;

Ų results and feedback from industry provided during companies’ interview process. Out of 130 selected Key Opinion Companies, 65 were interviewed by project partner responsible for the proper sector. These surveys aimed at listening to and understanding the technological needs of industry. In these interviews a structured questionnaire was used. It intended to focus and prioritise strategic research areas in respect to global, sectoral and company drivers.

The outcome of this conference allowed to filter and rank strategic research areas to meet industrial interests and priorities. Looking to the end-to-end visibility process, this conference can be positioned in the third phase of the process (filtering and assessment), as reported in Figure 3. This conference marked a new European event: it showed a collective ground for industrial research driven technologies where research organizations made possible to identify collectively new fields as well as to maintain the respective identities and to assess the respective contributions.

5. Conclusions

The objective of the Co-KM for innovation is to operate more effectively across the different sides that form the K-community and to proceed faster toward the common goal. For this aim the reference model helps managing the high-value knowledge in an open environment. This facilitates the correlation of need and competencies of the whole K-community. The goal is to turn knowledge into innovation tracking and making the end-to-end visibility of the advancements.

The creation of a high value stream for R&D through available competences and sound directions permits to sustain stakeholders in shifting the emphasis from measurable data to sustainable knowledge.

6. References

Cagnin C., Keenan M., Johnston R., Scapolo F., Barré R (Eds.), 2008. Future-oriented technology analysis: strategic intelligence for an Innovative economy, Springer.

Chesbrough H., Vanhaverbeke W., West J., (Eds.), 2006. Open Innovation:

Researching a New Paradigm.

Detlor B., 2004. Towards Knowledge Portals – from human issues to intelligent agents, Information Science and knowledge management, Kluwer Academic Publishers.

Eriksson E.A., Weber K.M., 2006. Adaptive Foresight Navigating the Complex Landscape of Policy Strategies, Second International Seville Seminar on Future-Oriented Technology Analysis: Impact of FTA Approaches on Policy and Decision-Making, Seville, Spain, 28-29 September.

Eumecha-pro, 2007. “European Mechatronics for a new Generation of Production Systems - The Roadmap”, 2007, http://www.thesame-innovation.com/Publi/ Fichier/eumecha-pro_the_booklet.pdf

European Commission Manufuture Platform 2006. ManuFuture Strategic Research

Agenda: Assuring the future of manufacturing in Europe, Report of the High

Level Group,

Futman Project, 2004. The future of manufacturing in Europe 2015-2020: the challenge of sustainability, Main report.

INEMI, 2007, International Electronics Manufacturing Initiative Roadmap, http://thor.inemi.org/webdownload/roadmapping/ 2007_Roadmap/07Exec_Summ_highlights.pdf

I*PROMS, 2004, Innovative Production Machine and Systems Network of Excellence - Vision and achievements, http://www.iproms.org/docs

ITEA, 2004, ITEA Technology Roadmap for Software- Intensive Systems 2nd edition, http://www.itea2.org/attachments/27/Executive_Summary-Chapter_1_ITEA_Roadmap-web.pdf

Jovane F., Boer C., De Pascale G. Manzini E., Mattucci M., Paci A.M., Rolfo S., Tagliaferri V., Verganti R., 2005. Area Tecnologie di gestione e produzione sostenibile. In: II Rapporto sulle prioritą nazionali della ricerca scientifica e tecnologica, Fondazione Rosselli (ed.), Milano, Guerini, pp. 310-349.

McInerney C. R., Day R. E. (Eds.), 2007. Rethinking knowledge management – from knowledge objects to knowledge processes, Springer-Verlag.

Mostefai S., Bouras A., 2006. What ontologies for PLM: a critical analysis, in Proceedings: 12th International Conference on Concurrent Enterprising, Milan, Italy, 26–28 June 2006, pp. 423–430.

Szostak R. (Ed.), 2004. Classifying

science, Springer-Verlag.Tokamanis C., 2006. Improve the competitiveness of

European Industry. ManuFuture Conference,

Westkämper E., 2006. RTD roadmaps from vision to implementation, ManuFuture

Conference 2006,

About the Authors:

Dr Augusta Maria Paci is

researcher from 1983 of Consiglio Nazionale delle Ricerche, CNR. In 2007

she achieved the Master in “Management Engineering” at the

Dr Cecilia Lalle is technical collaborator from 1988 of Consiglio Nazionale delle Ricerche. The main activities regard technical and management support in collaborative research-industry projects and in European and national research programmes, activities of research results transferring and education. She is author and co-author of scientific publications, project deliverable, and reports.

Engineer Maria Stella Chiacchio with a Master in Business Engineering is a PhD candidate in Economic and Management Engineering and has a research grant within the Emerging Production Paradigms Laboratory (EPPLab) of Consiglio Nazionale delle Ricerche. The main activities carried on concern analysis of collaborative research roadmaps for manufacturing transformation (products/services, processes and organisations), studies on impact assessment of research topics, costs/benefits analysis of enabling technologies for new/innovate products/services systems in competitive sustainable perspective.

Augusta Maria Paci, CNR Viale dell’Universitą 11, 00185 Roma Italy; Tel: +39 06 4993 7863; Email: augustamaria.paci@cnr.it

Cecilia Lalle, CNR Viale dell’Universitą 11, 00185 Roma Italy; Tel: +39 06 4993 7827; Email: cecilia.lalle@cnr.it

Maria Stella Chiacchio, CNR Viale

dell’Universitą 11, 00185 Roma Italy; Tel: +39 06 4993 7870; Email: mariastella.chiacchio@amministrazione.cnr.it